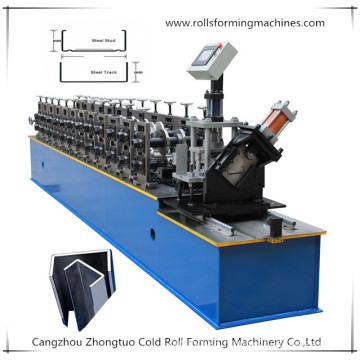

Light Keel Roll Forming Machine

| Payment Type: | L/C,T/T,D/P,Western Union,O/A |

|---|---|

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | 20ft container |

|---|---|

| Productivity: | 25m/min |

| Brand: | Zhongtuo |

| Transportation: | Ocean,Land |

| Place of Origin: | China(mainland) |

| Supply Ability: | 5 sets per month. |

| Certificate: | CE/ISO9001 |

Basic Info

Model No.: ZT-006-54

Product Description

Light Keel Roll Forming Machine

Support you money !! Support you service !! Support you technology !!

PLC control system !! Hydraulic cutting system !! Mult-language conversion system !!

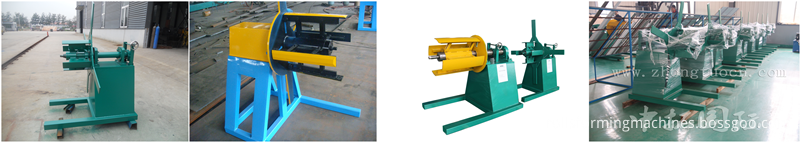

Keel Roll Forming Machine Decoiler System:

Usage: Passive uncoil pulled by roll forming system, support the steel coil and uncoil it in a turntable way.

| No : | Decoiler System Main Parameter : | |

| 1 | Loading capacity | 1.5T |

| 2 | Uncoiling width | 300mm |

| 3 | Inner diameter | 450-550mm |

Keel Roll Forming Machine Roll Forming System:

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

| No : | Roll Forming System Main Parameter : | |

| 1 | Length of the main part | About 3000mm*1000mm*400mm |

| 2 | Weight of main part | 3 tons |

| 3 | Voltage | 380V/50HZ3Phase (as customer`s request) |

| 4 | Roller fixer | guide column |

| 5 | Frame | steel plate welded/ Memorial arch frame type |

| 6 | Frame thickness | 25mm |

| 7 | Drive mode | gear |

| 8 | Material of rollers | GCr12MoV |

| 9 | Material of shafts | 45# steel with tempering |

| 10 | Diameter of shafts | φ40mm |

| 11 | Number of rollers | 10 rollers |

| 12 | Main power | 3kw |

Double working lines on the machine to finish the two profiles. Change the feeding unit to make another profile, the cutting head can move left and right by hand!

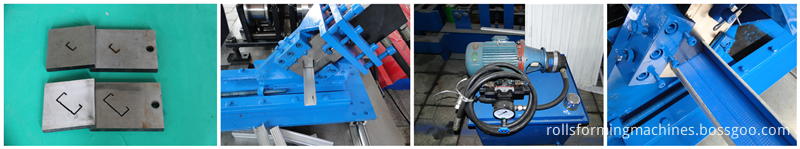

Keel Roll Forming Machine Automatic Cutting System:

Feature: Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. It contains one set of cutting tools, one hydraulic tank and one cutter machine. Hydraulic station is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

| No : | Cutting System Main Parameter : | |

| 1 | Material of blades | Gcr12MoV quenched |

| 2 | Power supply | hydraulic power |

| 3 | Frame | Pillar style with rack & pinion system |

| 4 | Stroke switch | non-contact photoelectric switch |

| 5 | Hydraulic motor Power | 3kw |

| 6 | Hydraulic oil: | 46# |

Keel Roll Forming Machine Electric Control System:

1. Adopted PLC , transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2. Other electric element are Delta.

3. Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Keel Roll Forming Machine Products receiving table:

It adopts welded steel and supported roller to transmit the products.

Keel Roll Forming Machine Our Service:

1. Installation and training of machine manufacturer:

a. If buyers visit our factory and check the machine, we will teach you how to install and use the roll forming machine for sale , and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service of roll forming machine for sale:

a. One year guarantee for whole roll forming machine for sale.

b. 24 hours technical support by email or calling:

c. If there is any problem found of steel roof sheet roll forming machinery, we will repair roll forming machine for sale for free in one year.

Keel Roll Forming Machine Company Information:

Cangzhou Zhongtuo International Trade Co., Ltd is a professional manufacturer located in northwest of CangZhou, as a long history of cold roll formingmachine production base. All products comply with international quality standards and are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe,South America, and Australia and so on.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine